Source: Focus interview

To produce this feed protein Shougang Lang Ze it is a subsidiary of Shougang Group, and it is the first enterprise in the world to realize the production of feed protein and fuel ethanol from steel industrial exhaust. Ten years ago, the company introduced gas fermentation technology to China to deal with Shougang's industrial exhaust. However, this technology has only been proven in the laboratory and is still a long way from industrial application. After years of technical research, Shougang Langze finally opened up the whole system process to achieve mass production.

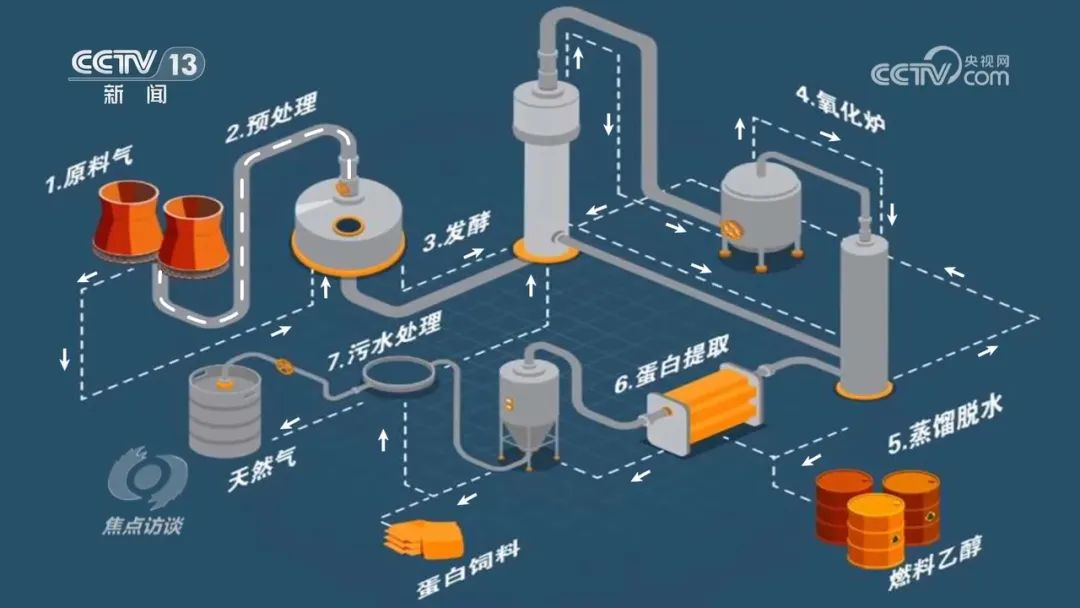

How does the seemingly magical operation of turning industrial exhaust into feed protein work?

Yang Yan, deputy general manager of Hebei Shoulang New Energy Technology Co., LTD. : "First, the industrial exhaust gas is transported to the gas pretreatment section through the pipeline, after simple compression and gas purification, it is transported to the core fermentation section by the pipeline, and the gas enters the top from the bottom of the fermenter tens of seconds time.”

Source: Focus interview

Next, industrial exhaust is turned into protein and ethanol by a bacterium called Clostridium ethanolum. In the whole production process, the work is Clostridium ethanolum,the staff just needs to monitor. It is biomanufacturing that Shougang Longze uses. The so-called biological manufacturing refers to the use of bacteria, cells, enzymes and other living organisms physiological metabolic function or catalytic function, through the industrial fermentation process to large-scale production of human needs of chemicals and polymer materials manufacturing process. It is an advanced production mode with industrial biotechnology as the core.

Tan Tianwei, president of Beijing University of Chemical Technology and academician of the Chinese Academy of Engineering: "What is the biggest core point? One is production with living organisms, and the biggest feature of living organisms is the reaction process, both

normal temperature, normal pressure; the second feature is that it can be used when the organism is transformed renewable raw material.”

Source: Focus interview

Biomanufacturing is a new production technology that integrates biology, chemistry, engineering and other technologies, with clean, efficient, renewable and other characteristics, and has the potential to change the world industrial structure in the fields of energy, agriculture, chemical industry and medicine. Experts say,bio-manufacturing will bring at least three major changes: reconstructing the production route of traditional chemical industry, replacing the access to traditional natural products, and subverting the traditional agricultural breeding model.

Liu Wenqiang, Secretary of the Party Committee and vice president of the CCID Research Institute of the Ministry of Industry and Information Technology: "Biological manufacturing is different from the traditional physical and chemical manufacturing mode, biological manufacturing innovates the material production mode, and takes organisms as the production medium, which will bring a series of great changes to the manufacturing industry; In addition, biofabrication, which is based on renewable biomass, is also critical for manufacturing to achieve the two-carbon goal."

Source: Focus interview

China has a large number of industrial exhaust resources. According to expert estimates, iron and steel metallurgy, petrochemical refining, cement and other industries annual output of industrial exhaust more than trillion cubic meters, if the use of 50% of which can produce 5 million tons of feed protein, reduce carbon dioxide emissions 120 million tons, save 160 million tons of grain, save 400 million acres of arable land.

China not only has a large amount of industrial exhaust, but also a lot of agricultural and forestry waste, which is also very suitable for the use of biotechnology. Bioethanol is commonly known as alcohol. At present, China mainly uses corn, wheat and other grains as raw materials to produce by fermentation technology. In Heilongjiang alone, 2.3 million tons of bioethanol is produced annually from grain. However, with the arrival of this cellulosic ethanol demonstration project, the situation of producing ethanol from grain will be broken. It is located in Hailun City, Suihua, Heilongjiang Province the first set of industrialization demonstration project using straw to produce bioethanol in China.

Li Chunling, chief engineer of SCIC Advanced Biomass Fuel (Helen) Co., LTD. : "The process of producing second-generation ethanol with straw is like this. After the straw is packed into the factory, it is purified and impurities are removed, and then the structure is exploded like popcorn, and then it is hydrolyzed into fermentable sugar by adding biological enzyme agents, and then it is turned into alcohol with yeast."

The traditional production of bioethanol is mainly by fermenting corn, wheat and other starch-rich grains to obtain sugar, and then using sugar to produce ethanol. The advantage of this technology is that it is difficult and easy to achieve, but the disadvantage is that it consumes food, and the phenomenon of competing with people for food and land with food affects national food security.Sdic uses straw to produce sugar, which is then used to produce ethanol.

After more than ten years of technical research, the company finally achieved mass production. Although the current production capacity of the demonstration project is only 30,000 tons,Approximate consumption 150,000 tons of straw,But its breakthrough is significant. According to statistics, the national straw production in 2021 is 865 million tons. Therefore, if this technology is fully promoted, it will be a major revolution against traditional technology.

Li Chunling: "Through technology research and development and independent innovation, we finally realized the transformation of non-grain based raw material structure." The benefit is that you can use resource-rich agricultural and forestry wastes that are sustainable, renewable and recyclable, and by using these agricultural and forestry wastes you can reduce carbon emissions and improve environmental pollution."

China is a big industrial and agricultural country, the consumption of resources is much larger, the corresponding emissions are also large, so there are conditions and it is necessary to resolve this problem through advanced technological means such as biological manufacturing and turn waste into treasure. It is crucial for building new quality productivity and promoting green, sustainable and high-quality economic development.

As one of the means to improve the productivity of new quality, biotechnology has been designated as a strategic emerging industry in China. To this end, China has formulated a number of policy measures. In 2022, the "14th Five-Year Plan" for Bioeconomy Development was issued, marking the official introduction of China's first Five-Year plan for bioeconomy. "Plan" clearly put forward,it is necessary to cultivate and strengthen the four pillar industries of medical and health care, bio-agriculture, bio-energy and bio-environmental protection, and bio-information.

Since the 18th National Congress of the Communist Party of China, the development of China's bioeconomy has made great achievements, and the categories of fine molecule industries have gradually increased, and the scale of core industries has grown rapidly. The Yangtze River Delta region has formed industrial clusters, and there are a large number of backbone enterprises in North and Central China.With the strong support of the state, a number of new technologies have been born, which lead the development direction of biological manufacturing in the future and redefine the future production mode.At the Tianjin Institute of Industrial Biotechnology of the Chinese Academy of Sciences, on July 24, 2018, a completely new technology was initially completed.

When it meets iodine, it turns blue, a characteristic of starch. However, the starch used by the researchers does not come from plants such as corn and potatoes, but from carbon dioxide.

This is an exciting technology, announced by the Tianjin Institute of Industrial Biotechnology of the Chinese Academy of Sciences in 2021,in the world for the first time to achieve the artificial synthesis of carbon dioxide to starch,The relevant results were published online in the international academic journal "Science" in September of that year, and the results were selected successively Top 10 Advances in Science in China in 2021, Top 10 advances in Life Science in China in 2021, etc.It achieved the breakthrough of creating organic matter from inorganic matter. This technology far exceeds the efficiency and speed of starch synthesis in crops such as corn, opening a window for the industrial production of starch,it also provides a new way to synthesize complex molecules from carbon dioxide.

Although the technology has been proven successful in laboratory conditions, it is still some distance from real industrialization, so scientists are working to break through the final technical barriers, once successful, the market will be unlimited.

Source: Focus interview

Source: Focus interview

CAI Tao, a researcher at the Tianjin Institute of Industrial Biotechnology, Chinese Academy of Sciences, said: "On the one hand, a lot of waste carbon dioxide, which may have an impact on the environment, can be turned into treasure; On the other hand, starch can be synthesized in industrial workshops, saving 80 to 90 percent of land and fresh water."

It has been proved that biofabrication can fundamentally change the production model of traditional manufacturing.The use of biological + medicine, biological + chemical industry, biological + energy, biological + light industry and other new production methods,there are a lot of new products, such as recombinant protein drugs, bio-aviation kerosene, biodegradable plastics and so on... biofabrication is considered to have the potential to lead the "fourth industrial revolution", and the future prospects are very broad. It is estimated that the global value of bio-manufacturing is close to $30 trillion.

In the future, with further breakthroughs in biotechnology, biological manufacturing is also expected to expand to mining, metallurgy, electronic information, environmental protection and other fields, with very broad development prospects, and become an important engine for economic growth.

Liu Wenqiang: "In the next step, the state will strengthen a series of deployments from the policy, enterprise and industrial levels to promote the development of the bio-manufacturing industry.In terms of policy, the relevant departments of the state are studying and formulating top-level planning documents for bio-manufacturing at the national level. In terms of industry, the relevant departments of the state will increase the investment of central financial funds and lay out a number of bio-manufacturing company platforms by fields and regions. In terms of enterprises, the relevant state departments will support enterprises to strengthen the innovation and research and development of core industrial strains and key enzyme preparations,we will enhance our capacity for independent innovation and promote the continuous emergence of innovative achievements."

Biological manufacturing, as a focus to enhance economic competitiveness, is also another important starting point for China to promote the construction of manufacturing power after green manufacturing and intelligent manufacturing. As a new quality productivity, the biological manufacturing industry has unlimited business opportunities, but the current development of this industry in our country has just begun.

At present, the added value of China's biological manufacturing core industry accounts for only 2.4% of industrial added value, and the room for improvement is very large.China has a good biofabrication foundation, coupled with a series of policies to boost the competitiveness of China's biofabrication industry on this new track will be more and more strong.